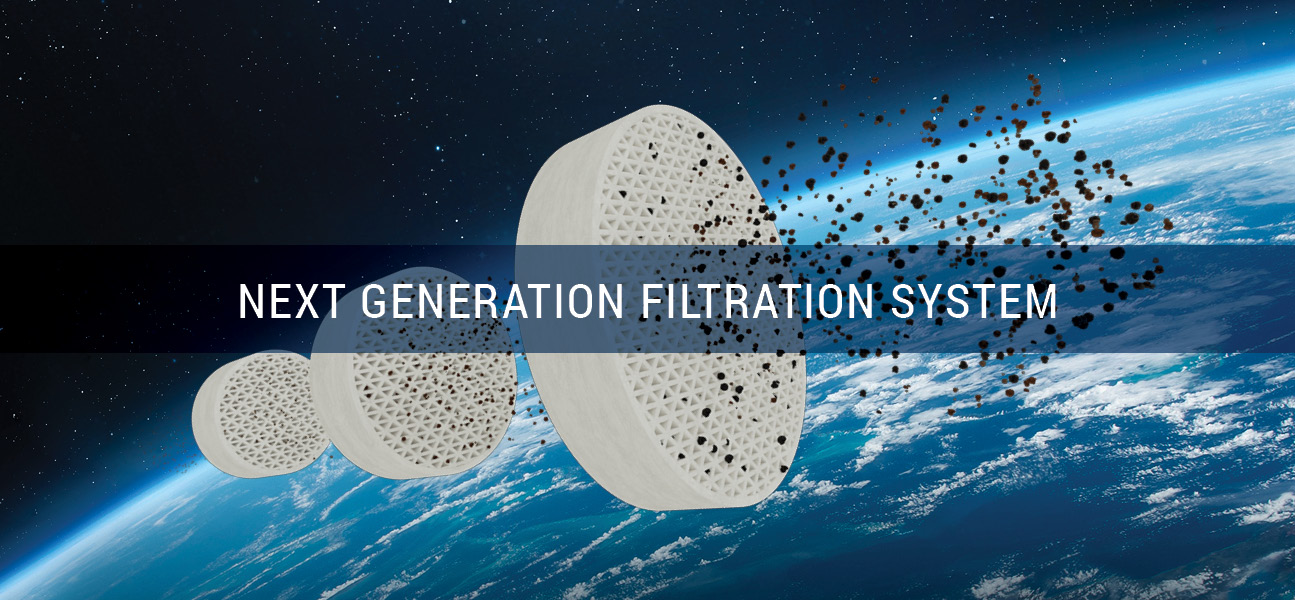

AFS Filter

AFS Filter (Advanced Filtration System) represents the most advanced and comprehensive pressure drop mitigation technology available to the refining and chemical industries.

The Next Generation of AFS has optimized uniform flow channels, creating non-restrictive flow distribution that maximises foulant capture.

These disks have been designed and optimized to mitigate pressure drop problems due to the build-up of various foulants in the grading and top catalyst layers of hydrotreating reactors and other fixed bed units.

UNICAT AFS Series is a licensed technology. AFS grading solutions have beensuccessfully installed in more than 500 applications.

Do you want to increase hydroprocessing unit run times by 50%?

ADVANTAGES OF AFS

- 50% + Longer Cycle Length, than reticulated product, due to having larger and 100% accessible void space for foulant capture and storage.

- Best option at capturing any size particulate.

- Easily doubles the run life of traditional grading in dP limited vessels.

- 3x STRONGER than reticulated product.

AFS UNIQUE FEATURES

- Available in promoted type for mild HDS hydrogenation, silica removal and

dernetalization.

- High crush and physical strength provides minimal dusting and breakage during loading and unloading. (3x STRONGER than reticulated disk)

- Available from 10 mesh to 50 mesh filter patterns in most sizes providing exceptional flexibility in design.

- Available with active Surface Area exceeding 60 M2/g to 110 M2/g so it can be used as catalyst substrate while maintaining filtration capability.

- Well suited for high pressure applications such as CFH, GOHT and HCU reactors as well as less severe applications such as NHT and DHT.

dernetalization.

INNOVATION IN DESIGN

The Next Generation of AFS has improvements in geometry. Shape and design have evolved along with a deeper understanding of dynamics which influence filter capacity and pressure drop.