Magcat® Textured Catalyst

Magcat® Textured Catalysts formed utilising polymer ceramic technology rather than the traditional pressure method. This allows optimised strength, geometric surface area and surface texture.

Our textured catalysts create a more turbulent gas flow around the catalyst and therefore disrupts the thin static gas layer at the inside of the tube wall. This results in a higher heat transfer coefficient (HTC), reduced tube skin temperature and accelerated mass transfer of reactants to the active catalyst site.

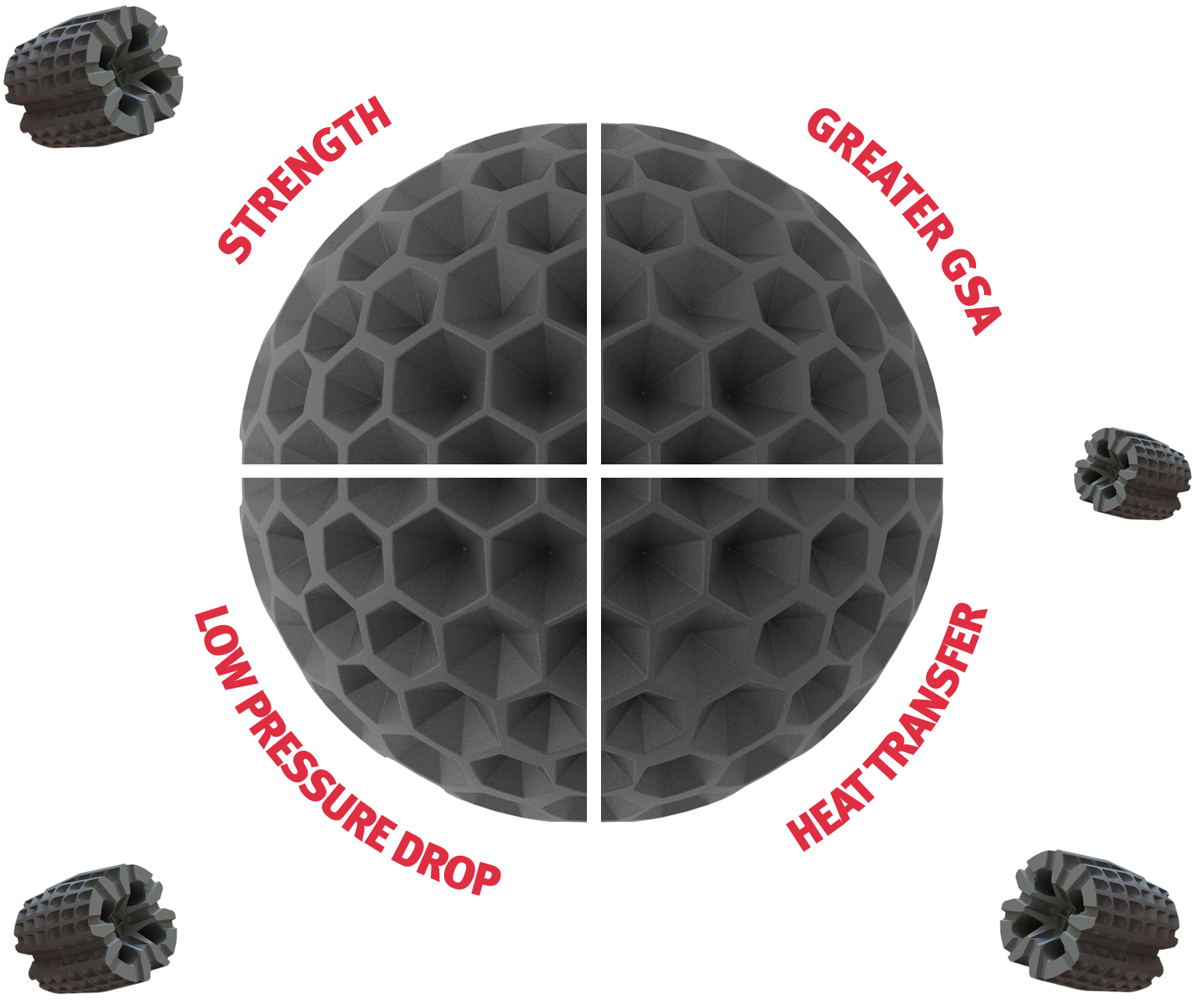

Benefits of Magcat® Textured Technology

STRENGTH

- Magcat > 300 lb/ft (+50% higher than competitor*)

- Higher Attrition Resistance

- Stronger pellets that pack better

* Typical dependant on material type

* Typical dependant on material type

GREATER GSA

- +30% improvement in active surface area

- More sub-surface area available for chemical reaction

- Optimised Nickel loading and placement avoiding wastage

LOWER PRESSURE DROP

- More methane processed

- Reduction in operating costs

- Greater strength reduces pressure drop increase over life of catalyst

HEAT TRANSFER

- Maximum Heat Transfer

- Uniform packing reduces thermal stress on the reactor tube

- Extending tube life span therefore reducing cost of re-tubing

Our Magcat® Textured, steam methane reforming (smr) catalysts are designed to improve heat transfer coefficient, provide high intrinsic strength and lower pressure drop across the process. These properties deliver performance benefits at constant plant rate including lower pressure drop; lower tube skin temperatures; and reduced reforming firing. This gives an overall increase in operation efficiency at the given operating conditions.

Traditionally smr catalysts form the catalyst support from tabletting/pelleting alongside high temperature firing to stabilise the structure. This technique gives a smooth external surface.

Products

Pre-Reforming

Primary Reforming

Secondary Reforming

DRI

Ammonia Dissociation Catalyst

Comparison Drop Loading – Magcat® Textured Sphere VS Competitor

Innovation

In April 2022 Magma was one of 226 organisations to be awarded with a prestigious Queen’s Award for Enterprise. Recognised for their excellence in the category of Innovation for their work on the Magcat® Catalyst product.

“We are committed to growth as our focus and believe innovation is the best enabler for this.

So, the research development and deployment of an innovation pipeline is central to our future growth plan.” – Mark Stuckey, CEO

Innovation in Textured Catalyst for Steam Methane Reforming (SMR)

The production of hydrogen is forecast to grow significantly over the next 10-15 years due to the growth in fuel cell technology.

The lack of innovation in SMR catalyst development over the last 20 years and the need for more hydrogen made the development of a new catalyst that can improve hydrogen production and lower energy costs a significant step forward.

Using expert knowledge on ceramic production a new catalyst that innovates in the areas of texture, shape, surface area, strength, catalytic activity, porosity, and heat transfer was developed.

Magcat® Textured Catalyst provides:

- More flow through the reformer tube without an increase in methane slip

- Lower tube temperatures by improving heat transfer and therefore increasing tube life and efficiency.

- Reduced energy costs and footprint of the reformer

- Less pressure drop over time due to improved crush strength

“We are committed to growth as our focus and believe innovation is the best enabler for this.

So, the research development and deployment of an innovation pipeline is central to our future growth plan.” – Mark Stuckey, CEO